Facilities

Our lab is in building NW13 housing state-of-the-art tools for nuclear fuels and alloy processing and characterization. In addition, we use shared facilities at MIT, national laboratories, national computing centers and synchrotron sources in the US and around the world.

5TA Tri-Arc Melt Furnace

The furnace system consists of the Tri-Arc Furnace, a Resistor box, a D.C. power supply, and a set of water-cooled power cables to bring power and water to the furnace. Because of its simplicity, ease of access, and small volume, the furnace is easily purged. It will be used for sample arc casting, powder melting, compound synthesis and annealing.

Photo credit: Centorr vacuum industries

Glovebox

The group has an Mbraun Uni-Lab Pro DP dual station glovebox housing a ball milling machine and for storing and handling pyrophoric samples. It is equipped with a fully automatic 1-filter column gas circulation system for cleaning inert gas and to absorb O2 and H2O. The system is operated with Ar at pO2 and pH2O < 0.1 ppm. The glovebox is used for preparing air sensitive sample.

Photo credit: Mbraun Inc.

Ball milling machine

The planetary ball mill is easy-to-use, and lubrication-free. It is suitable for mixing, homogenizing, fine grinding, mechanical alloying, small sample preparing, and new alloy development. The systems feature lubrication free, small volume, high efficiency, low noise, and quick clamp. The ball milling machine is incorporated into the glove box. When using vacuum jars, samples can be processed in a vacuum or inert gas environment. The system can be used to smash and blend various products of different materials and granularity with dry or wet methods.

Siemens / Bruker D5000 X-ray Powder Diffraction (XRD) System

The Siemens D5000 diffractometer is used for structure and phase composition analysis of as fabricated and post experiments samples. The samples including radioactive materials can in a powder or pellet form. The diffractometer operates at 40 mA current and 35 kV voltage and is used in combination with airtight specimen holder additively manufactured in house.

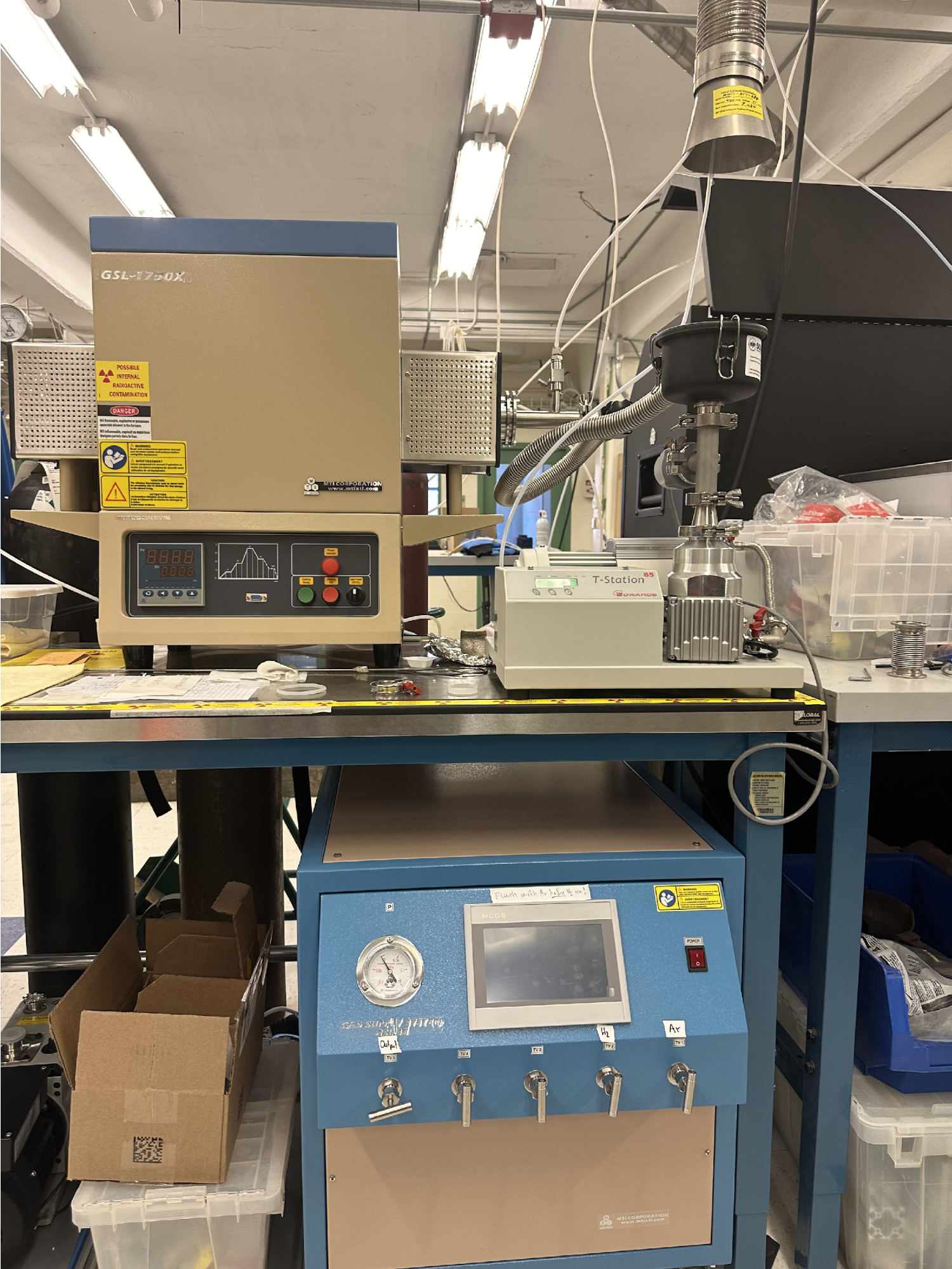

High temperature vacuum and atmosphere tube furnace (1750 oC max)

The GSL-1750X-60 is a UL and CE-certified compact furnace with a maximum working temperature of 1750 oC. The temperature is set using a digital controller with a high degree of accuracy of +/-1 oC. The tube is used for sintering of wide variety of materials under vacuum and other gas conditions. The tube connected to a gas mixer for accurate gas control during sintering or annealing.

Being acquired:

Twin-Jet Electropolisher

The Automatic Twin-Jet Electropolisher is used for the electrolytic thinning of TEM specimens. The twin-jet technique simultaneously polishes both sides of the specimen, creating electron transparency within a few minutes.

Photo credit: Fishione Instruments

Model 170 Ultrasonic Disk Cutter

The Model 170 Ultrasonic Disk Cutter is an effective device for the initial cutting of TEM specimens from hard/brittle materials. This rapid cutting process minimizes specimen damage and yields high-quality samples in just a few minutes. An automatic terminator stops cutting when the tool is in contact with the specimen plate.

Photo credit: Fishione Instruments

Model 200 Dimpling Grinder

The Model 200 Dimpling Grinder is an easy-to-use, state-of-the-art, mechanical thinning instrument designed for the reproducible preparation of high-quality TEM specimens. The Model 200 features grinding rate control which determines the rate at which material is removed. Microprocessor-based control circuitry automatically and precisely terminates the grinding process when the desired specimen thickness is achieved.

Photo credit: Fishione Instruments

High Performance Computing

Access to the MIT SuperCloud. Each node has 40 CPUs cores, 2 Nvidia Volta GPUs, and 384 GB of RAM. The nodes are connected via a 25 Gb network to several petabytes of data storage. The MIT SuperCloud is the largest interactive supercomputer in the world and is one of the largest supercomputers at a US University.

National User Facilities

In addition to in-house facilities at MIT, our research relies on state-of-the-art national facilities, primarily Advanced Photon Source at Argonne National Labotory, National Synchrotron Light Source II at Brookhaven National Laboratory, Center for Functional Nanomaterials at Brookhaven National Laboratory and the European Synchrotron Radiation Facility.